IBA: From eradicating cancer cells to destroying PFAS in drinking water, IBA never shies away from a challenge!

- Member

- IBA

Since it was set up in 1986, this spin-off from the Department of Nuclear Physics at UCLouvain has grown by leaps and bounds.

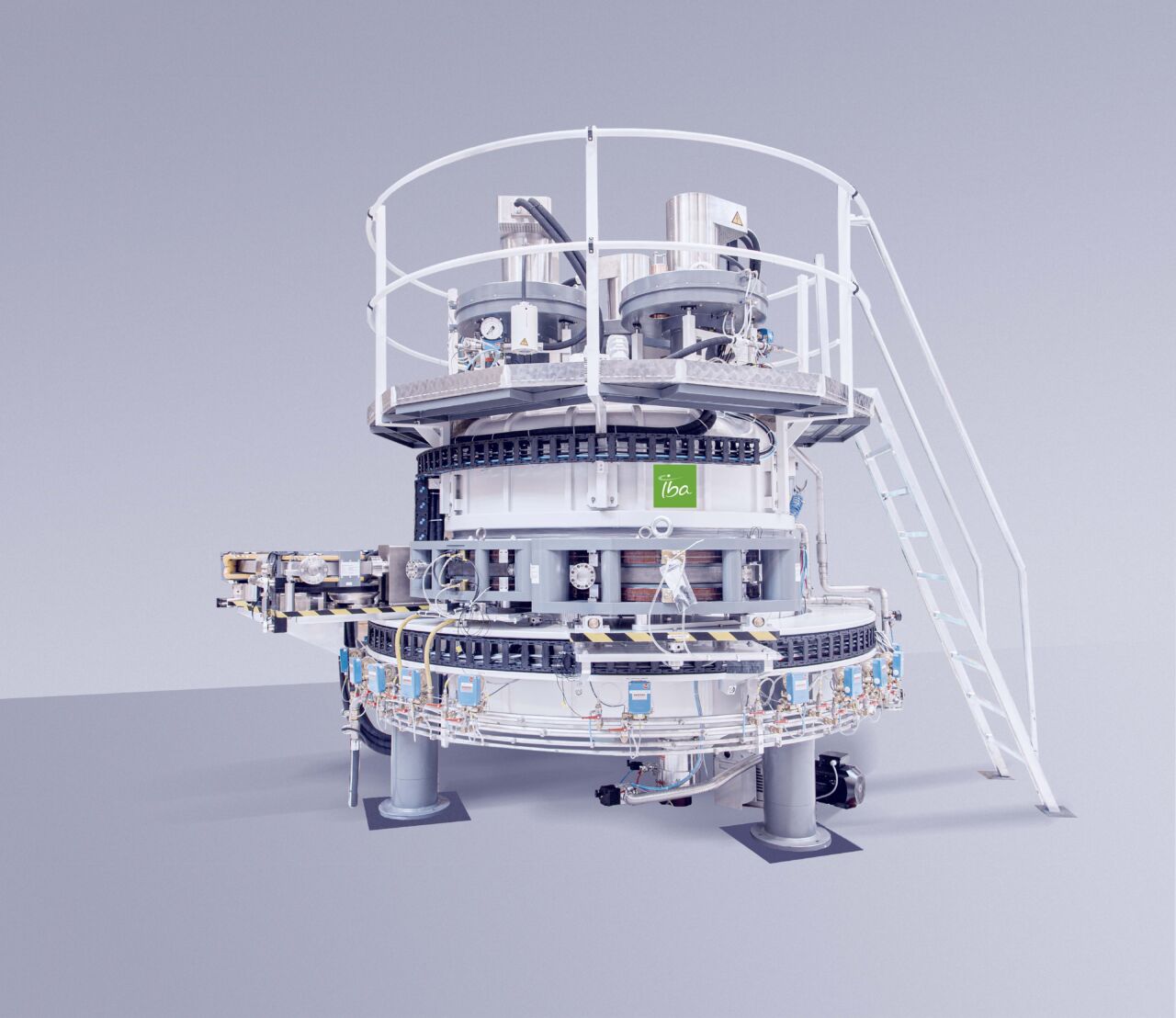

It has to be said that their system, the miniaturization of the cyclotron, is quite revolutionary: among other things, their solution gives hospitals access to a particle accelerator for the treatment of cancer by proton therapy - the most advanced form of radiotherapy - which they can install directly on their premises.

The company also provides equipment and services in the fields of nuclear medicine, sterilization, and dosimetry. All sectors in which it is a world leader.

- Ecosystem

-

- MedTech

- Success criteria

-

- Sales revenue inscrease

- Job creation

- Long-term innovation

- International development

- Disruptive innovation

IBA in a few figures and countries

In the second year of its existence, no fewer than 4 contracts were signed with Japan, Australia, China and the United States. Very quickly, the payroll grew to around one hundred people.

In 1998, IBA was floated on the stock exchange with spectacular results: demand for its shares outstripped supply by a factor of 32. Since then, the company's size and markets have continued to grow. To date, IBA has sold more than 70 proton therapy systems and nearly 700 particle accelerators in all fields.

The company currently employs more than 2,000 people in some twenty countries, half of them in Belgium. The company's order book stands at an impressive €1.4 billion, while sales will reach €429 million by the end of the 2023 financial year, up 19% on 2022. Gross margin was 31%.

The MecaTech cluster, an essential partner in the multinational's development

No fewer than 7 projects have been carried out with the support of the MecaTech cluster. One of the first collaborations, the Win-GTR project, still accounts for a large part of IBA's turnover.

Launched in 2009, the aim of this project was to make proton therapy accessible to as many patients as possible. It led to the launch of the Proteus®ONE, a solution that centralizes all the elements required for treatment in a single, small space, optimizing operations for therapists and significantly reducing costs.

MecaTech brought together all the skills required for the project, ensured its implementation and monitoring, and facilitated the marketing of the product both locally and internationally. This ambitious challenge involved Ateliers de la Meuse, where the first unit was assembled and which continues to machine and assemble each Gantry (irradiation gantry), UCLouvain, Sirris and Aériane.

The figures for 2023 speak for themselves

And show that IBA has over 40% of the proton therapy market, with more than 70 proton therapy centers sold and more than 120,000 patients treated.

In the first half of 2023, sales and services in proton therapy are expected to exceed €95 million. And the next few years look bright, with 10 machines sold to Spain, and numerous sites under development in the USA, China, Italy, Poland, Georgia, Egypt and Israel…

Innovation, even on a small scale, is a sine qua non for growth

Yves Claerboudt, R&D Director, says: “Innovation is essential for a Belgian company selling abroad. When you're up against competitors like Hitachi and Siemens, it's complicated. We don't have the same resources to finance innovation programs, unlike these companies, which can do so solely out of their own funds. The Walloon Region's support is therefore invaluable to us in financing these R&D programs, in agreement with our shareholders. And the MecaTech cluster is also essential in helping us to find local partners. It's much easier to work with a partner who lives 20 km away than a company 600 km away. That's part of the dynamic of the Walloon and Belgian economy.”

One of the projects under study at IBA in 2024 is the destruction of PFAS using a technology already in use in one of its particle accelerator models.

This promising technology, which should be applicable to this new field of use within 3 to 5 years, will make it possible to treat waste with a high concentration of PFAS without going through incineration, which is energy-intensive and generates large quantities of CO2.

The process could also be used to treat drinking water and groundwater.

Story to follow!